Applied to suction pressing, large diameter roll with blind hole,and shoe pressing.

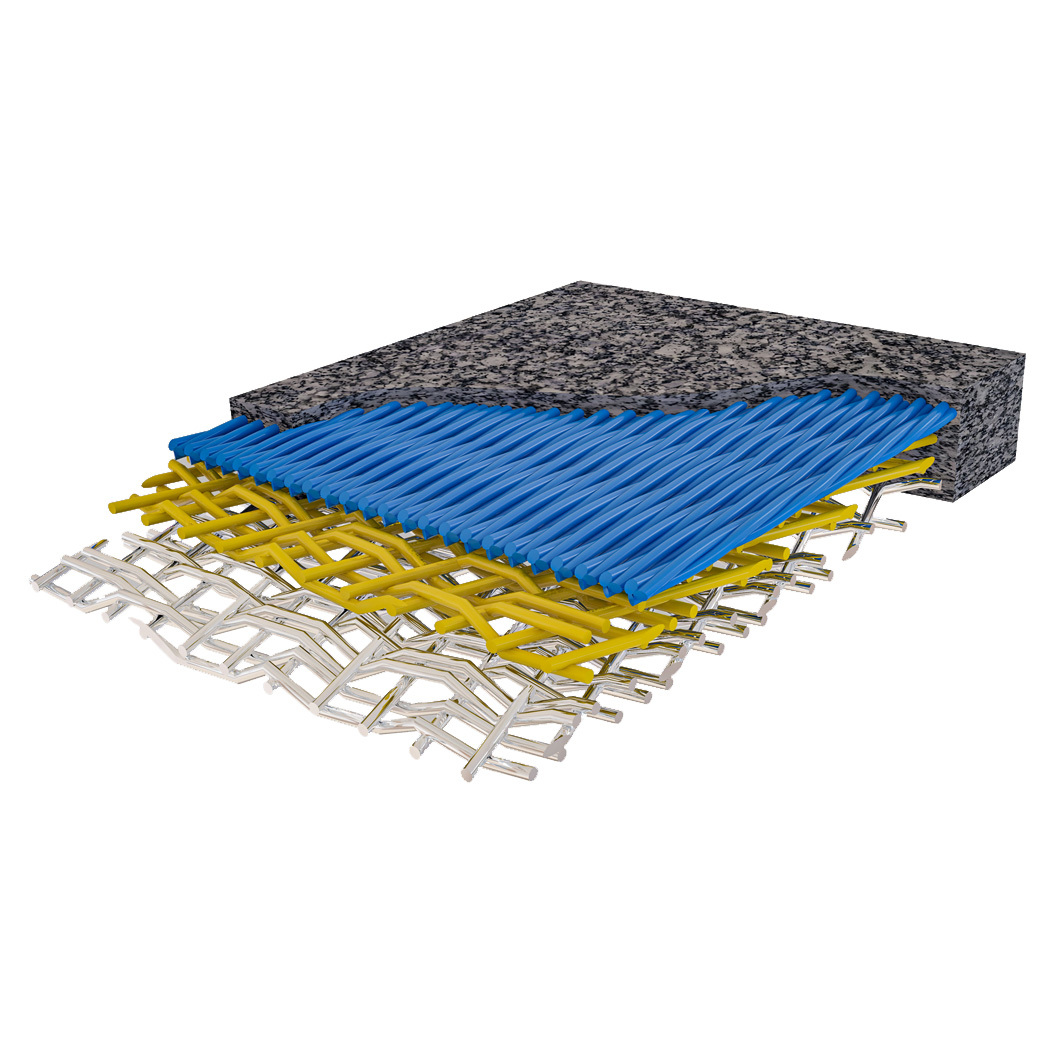

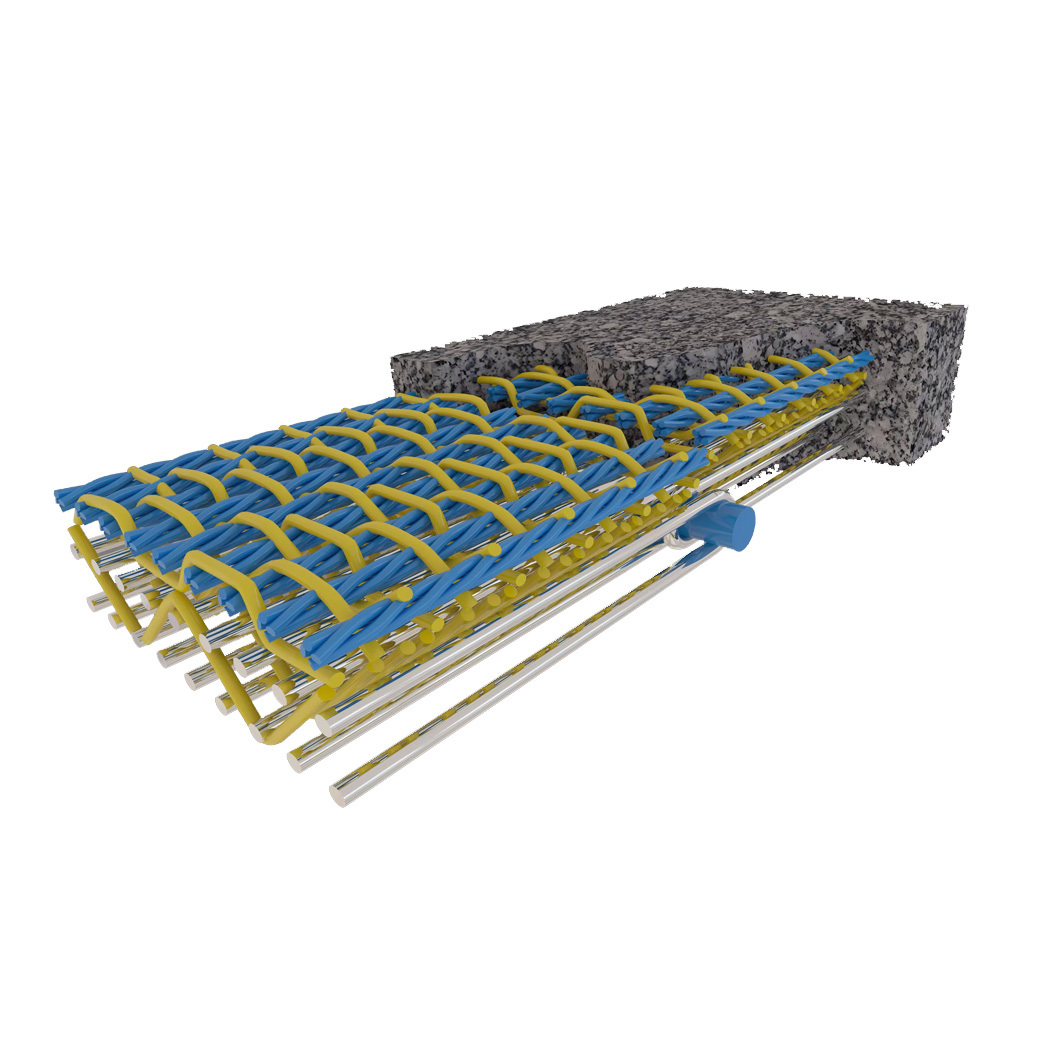

Primarily a three-layer base fabric structure.

Contains one or two layers of all-monofilament base fabric structure.

Easy to clean, anti-clogging, good resilience.

Air Permeability of about 50-80cfm

Fast Start-up for PU position

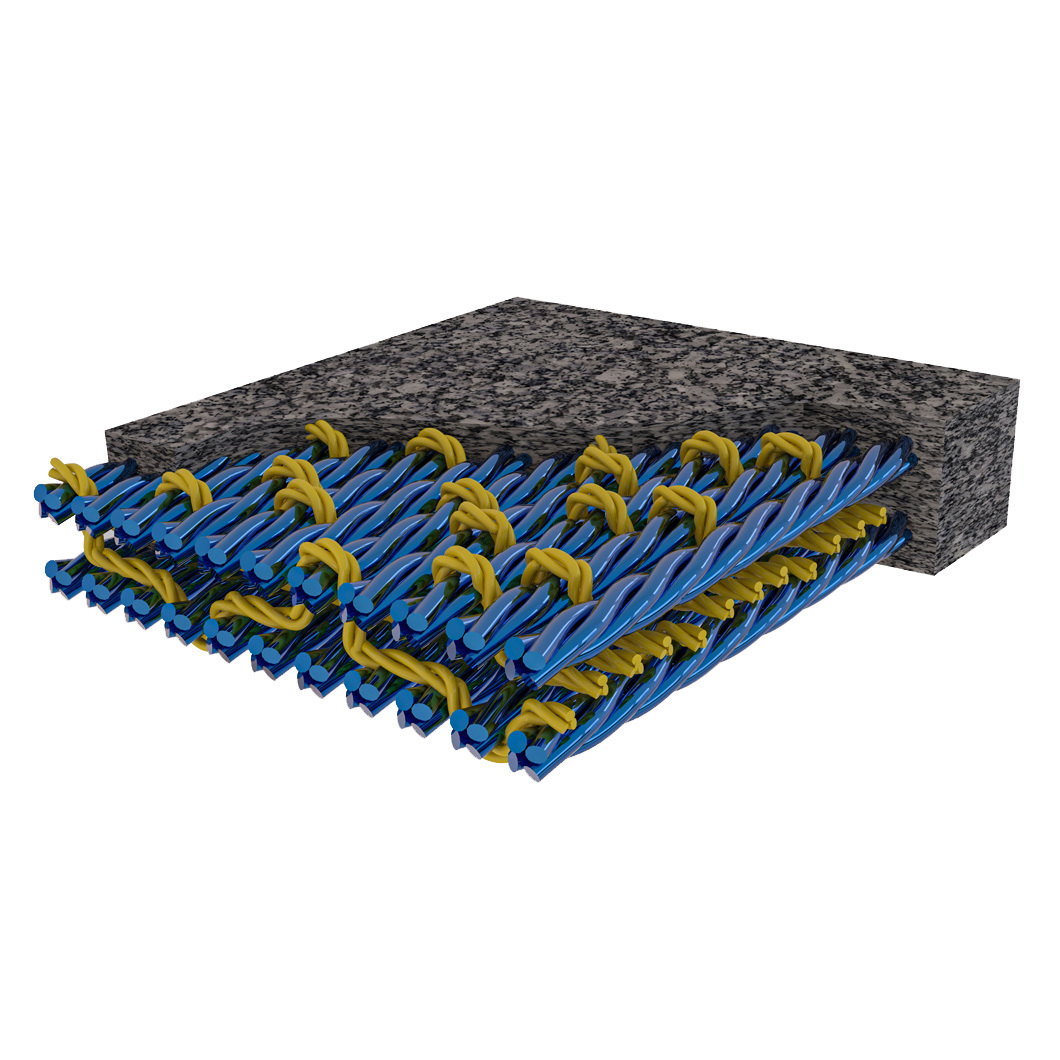

Two or three-layer base fabric structure

Fine felt surface

Low re-wetting design of the final pressing process

Air permeability about 45-65cfm

Meeting the precise needs of different paper types

Adaptability of felts for the same paper machine with different paper types

Air permeability of about 35-55cfm

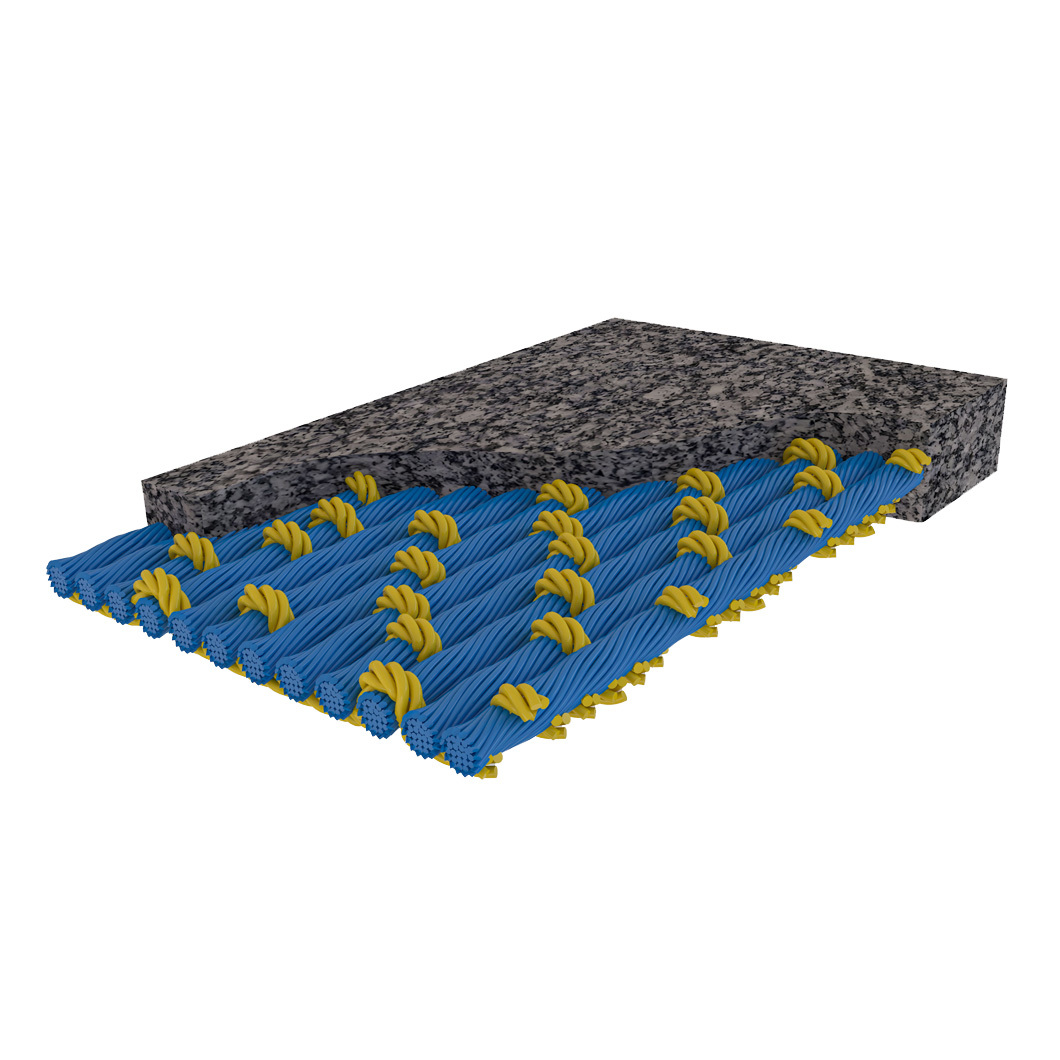

High-speed Tissue paper series

Felt design for multi-variety paper production

Ensuring the surface effect of low-grammage paper

Dedicated to optimizing felts to reduce steam consumption

Air permeability of about 20-40cfm

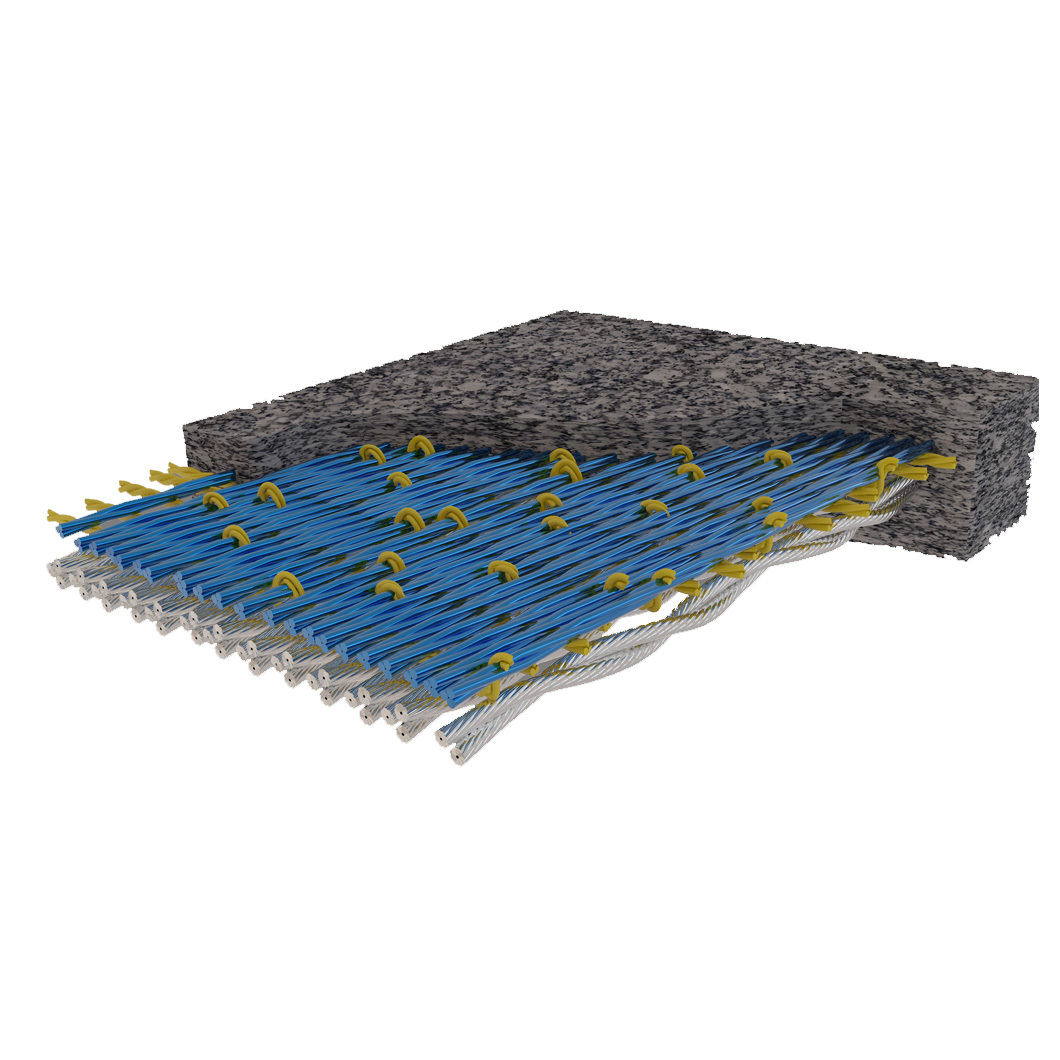

Heavy paperboard and pulp board series

Suitable for heavy paper grade

Meets the needs of high pressure load position

Endless or seamed felts

Air permeability of about 90-140cfm